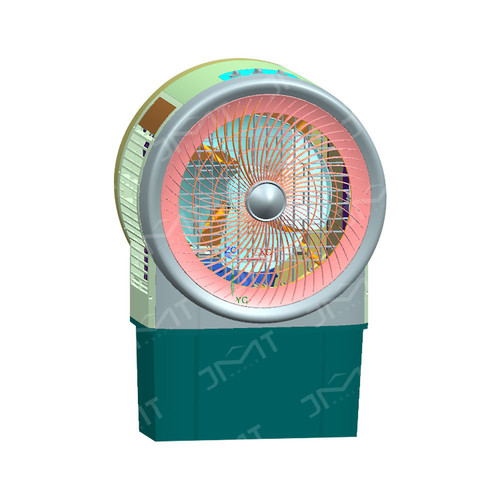

JMT MOULD is the most useful company of industrial air cooler molds, and has rich experience in manufacturing air cooler molds for household.

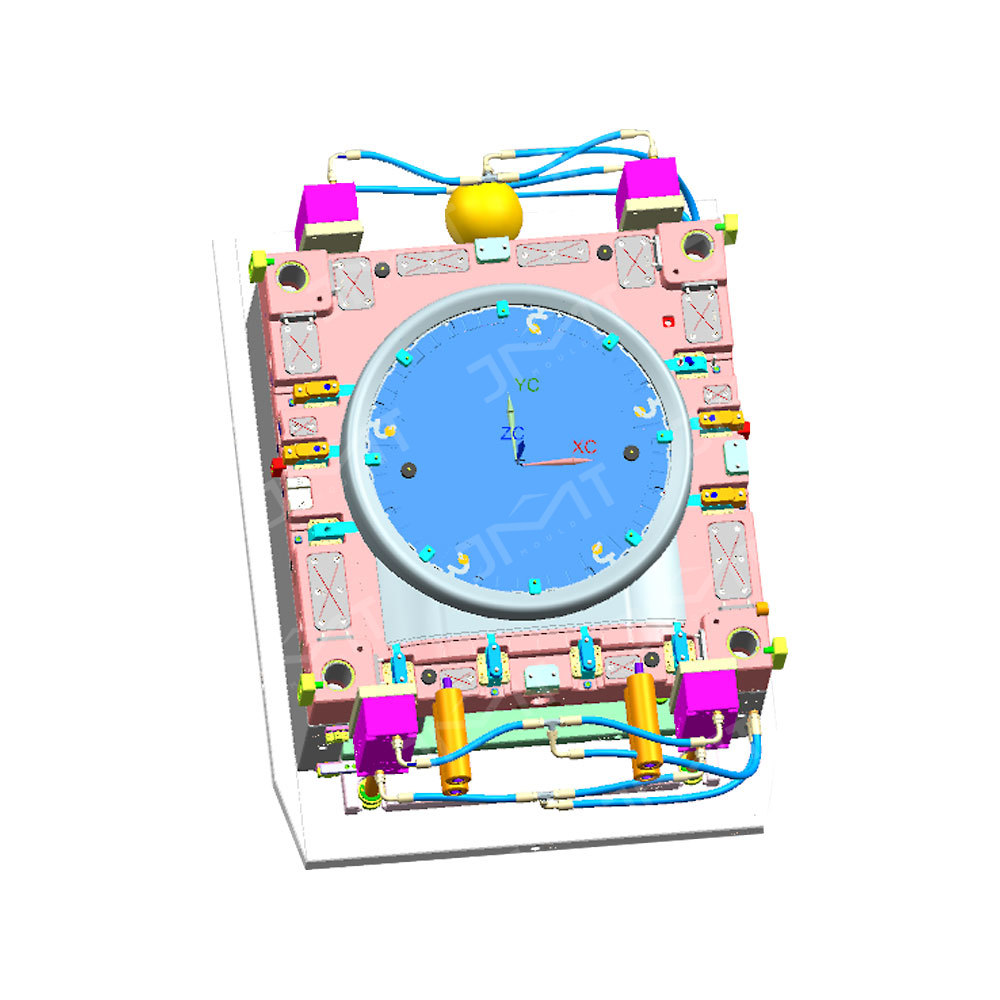

The biggest characteristic of the air cooler mold is the gas auxiliary and cane design, which has high requirements for the CNC machining. How to carry out the gas auxiliary is also a big requirement for the mold design

Household cold air, his specific volume is small, their power would be no big industrial cooling fan mould, household air cooler and air-conditioning fans, can add wet curtain, air through the air cool and wet curtain, hot weather can join ice crystals, the wind blowing out temperature will reduce a lot, and it don't have too much different with the air conditioning, so why the name is air-conditioning fans. Ice crystals are easy to use, and when frozen in a refrigerator, they melt in an air-conditioned fan, releasing cool air. Ice crystals can be prepared more than a few pieces, easy to use in turn.

|

Part Name

|

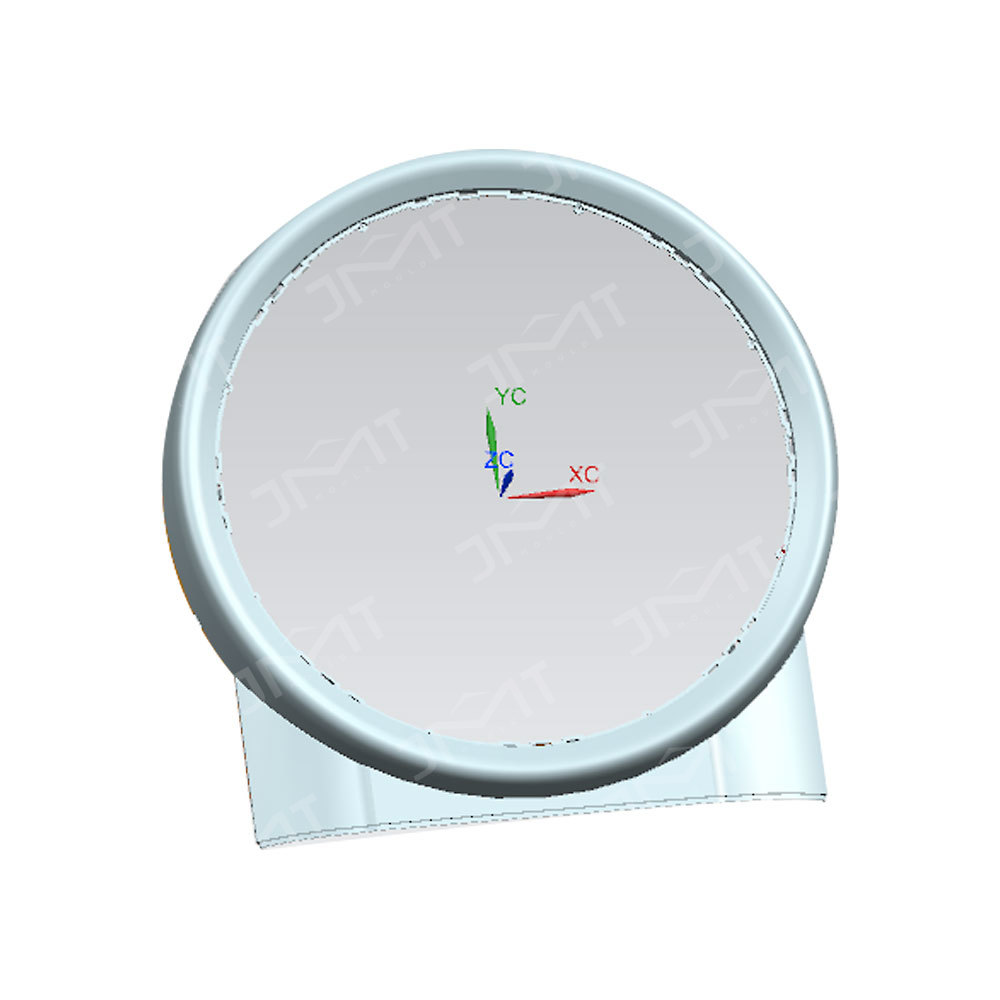

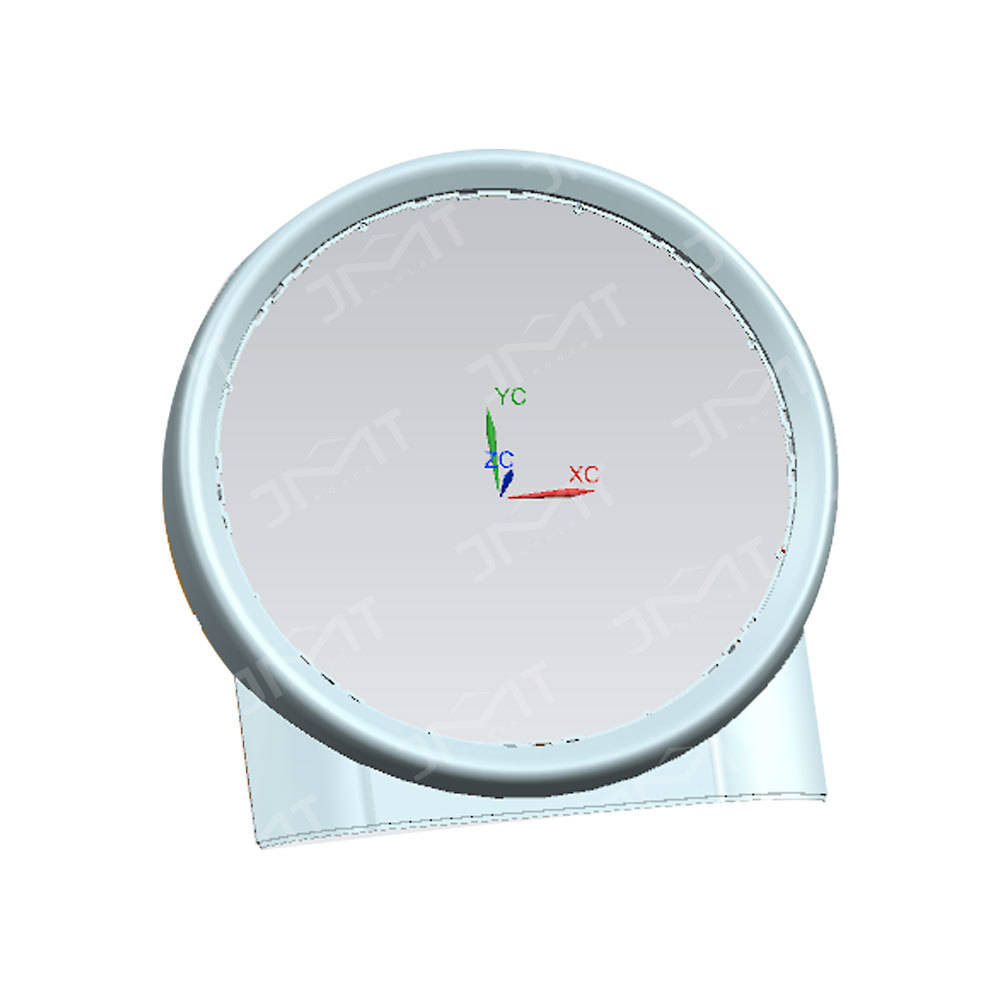

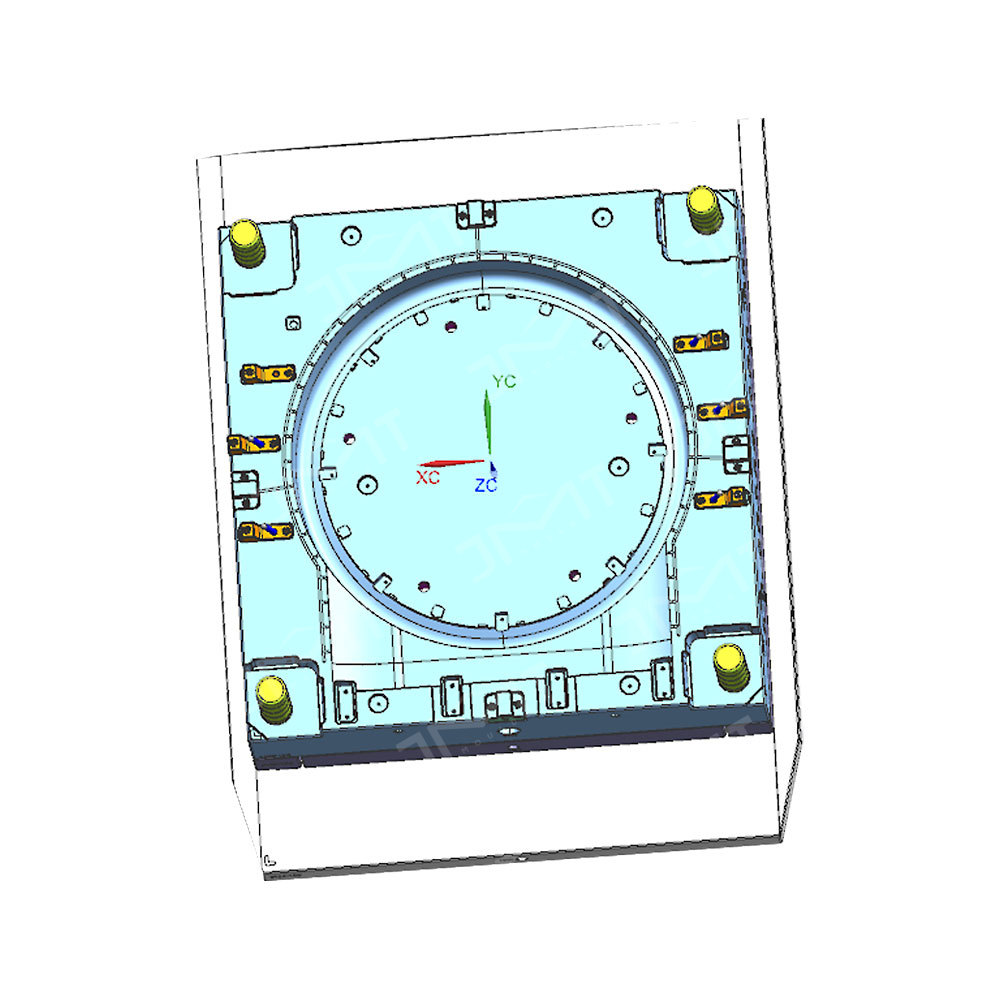

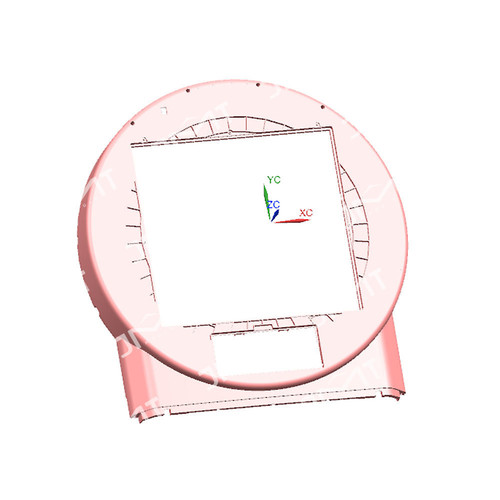

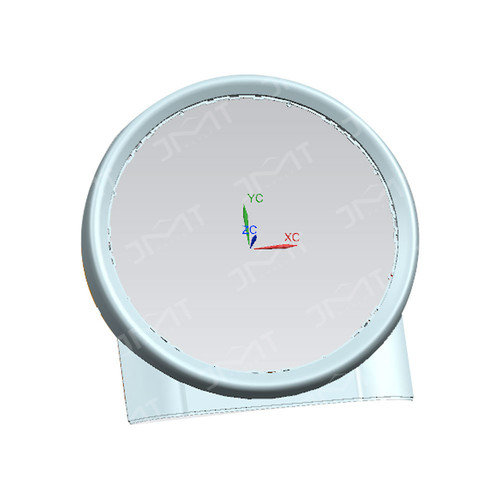

Plastic Air Cooler Front Frame Mould

|

|

Plastic resin

|

>PP<

|

|

Mould cavity steel

|

1.2311H

|

|

Mould Core steel

|

1.2311H

|

|

Gate system

|

Hot runner

|

|

Manufacture time (day)

|

60 DAYS

|

|

Mould life

|

500,000

|

|

Cooling line connector type

|

DME NS350 SERIES quick coupling, excellent cooling system design, cooling design will as many as possible to cooling best

|

Tel: +86-18158622819

Tel: +86-18158622819  E-mail: [email protected]

E-mail: [email protected]

English

English Español

Español عربى

عربى