Excellent crate mold planning is: on the premise of meeting customer requirements, low processing cost, difficult processing, short processing time. Therefore, we not only need to fully digest the needs of customers, but also need to understand the injection molding machine, mold structure, processing technology and the processing capacity of the mold factory itself. Therefore, in order to improve the level of mold design, the following operations should be carried out.

Understand every detail of each mold plan and understand the purpose of each part in the mold. In the planning, reference to the previous similar planning, understand the mold processing and product production status, learn from experience and lessons. Understand the process of injection molding machine in detail, deepen the connection between mold and injection molding machine.

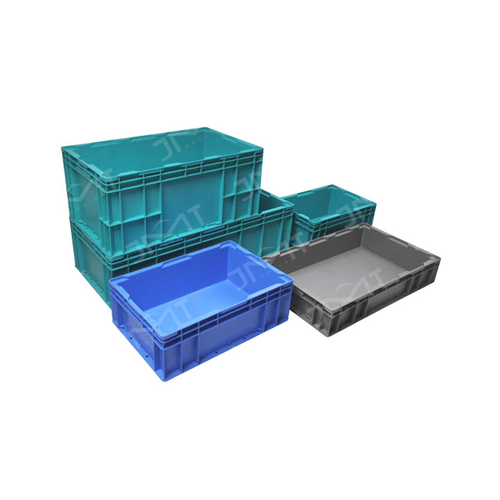

Easy to process and low cost Through the current sophisticated plastic molding process, plastic crates are more controllable than metal shells in mass production, so in addition to the lower cost, fruit plastic crate reduce unnecessary waste of resources in terms of time and processing.

JMT MOULD want to provide professional service and good quality for customers.

|

Part Name

|

fruit crate plastic mould

|

|

Plastic resin

|

>PP/HDPE<

|

|

Mould cavity steel

|

718

|

|

Mould Core steel

|

718

|

|

Gate system

|

Hot runner

|

|

Manufacture time (day)

|

60 DAYS

|

|

Mould life

|

1,000,000

|

|

Cooling line connector type

|

DME NS350 SERIES quick coupling, excellent cooling system design, cooling design will as many as possible to cooling best

|

Tel: +86-18158622819

Tel: +86-18158622819  E-mail: [email protected]

E-mail: [email protected]

English

English Español

Español عربى

عربى