Mould Description

|

Part Name

|

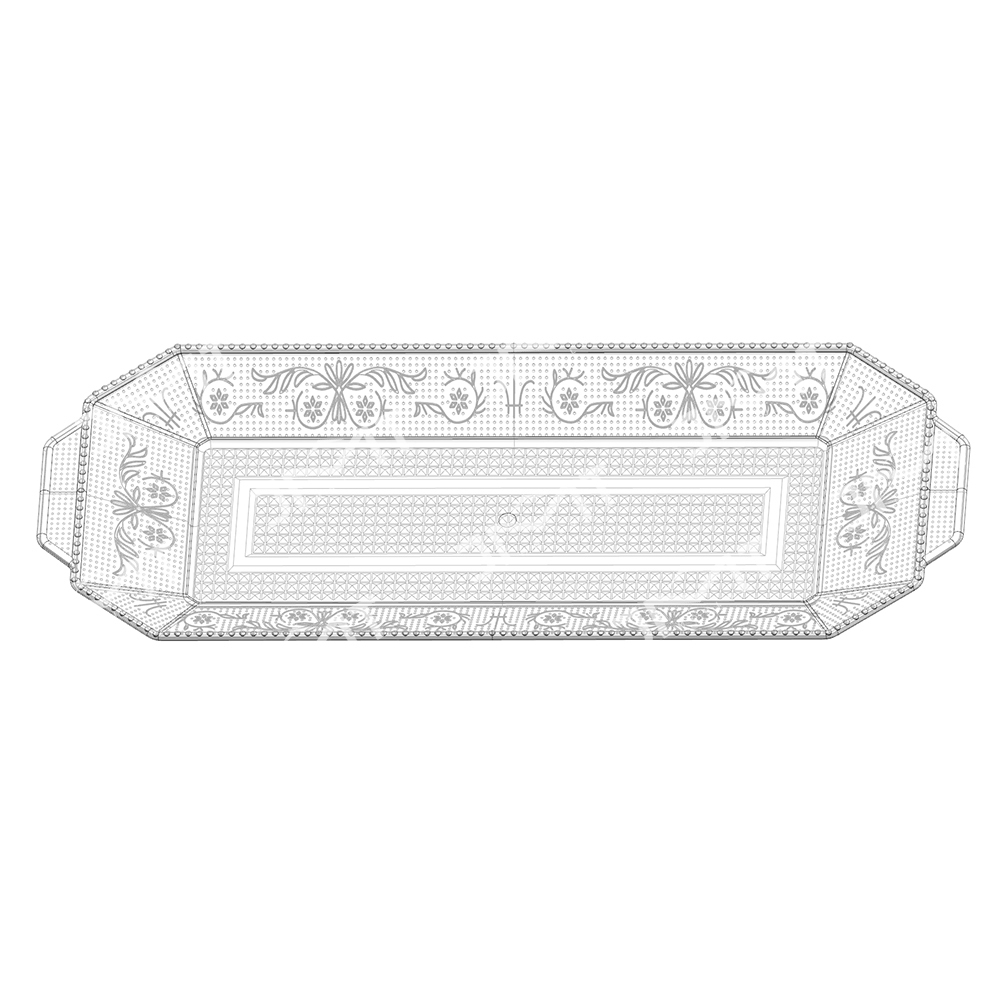

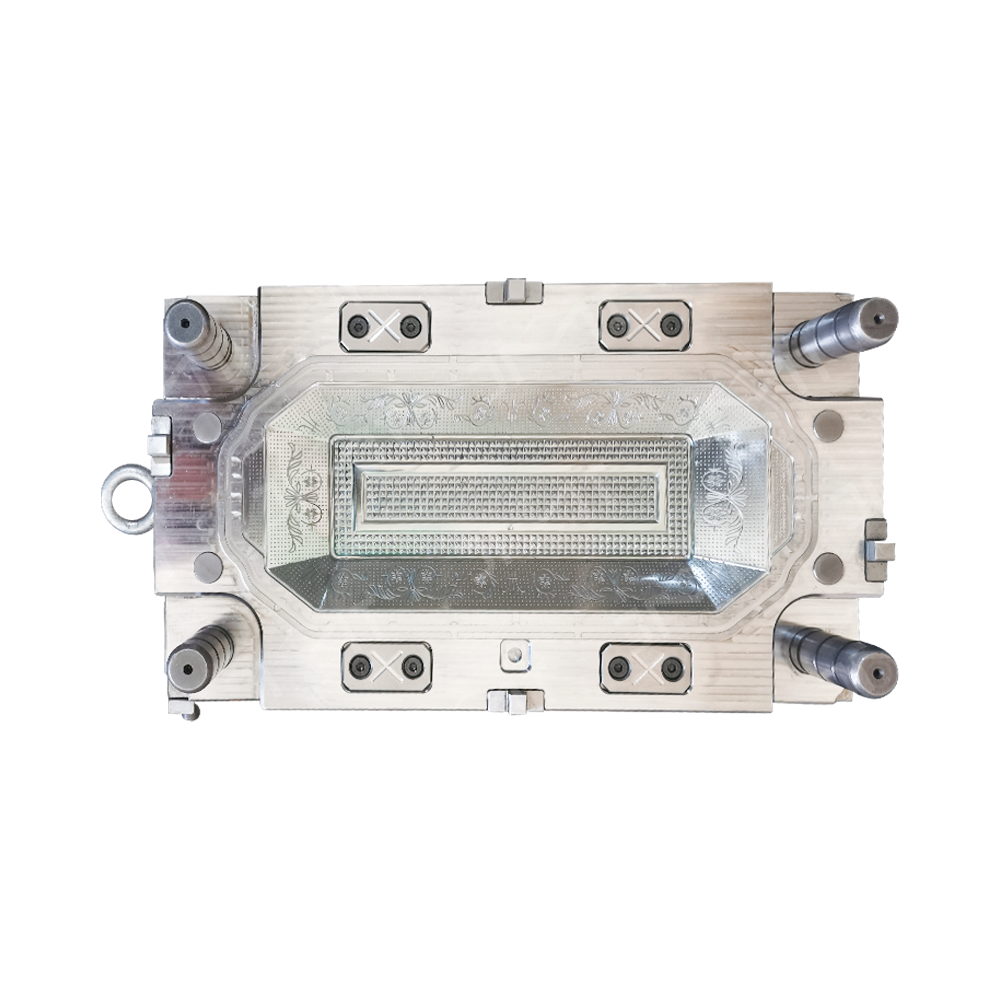

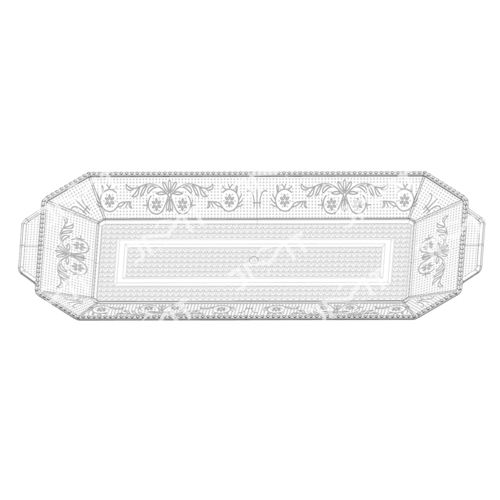

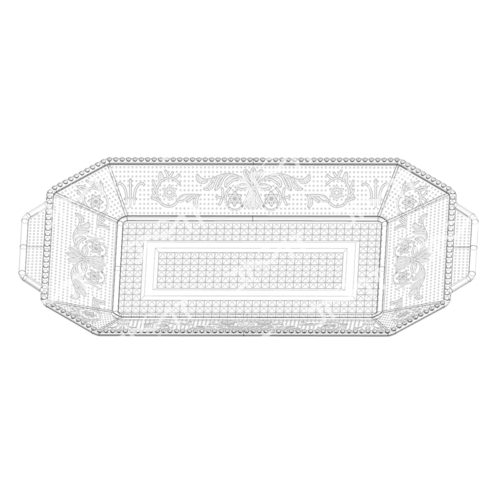

Rectangular plastic food bowl transparent crystal pattern mould

|

|

Plastic resin

|

>PP<

|

|

Mould cavity steel

|

Germany 2738H

|

|

Mould Core steel

|

Germany 2738H

|

|

Gate system

|

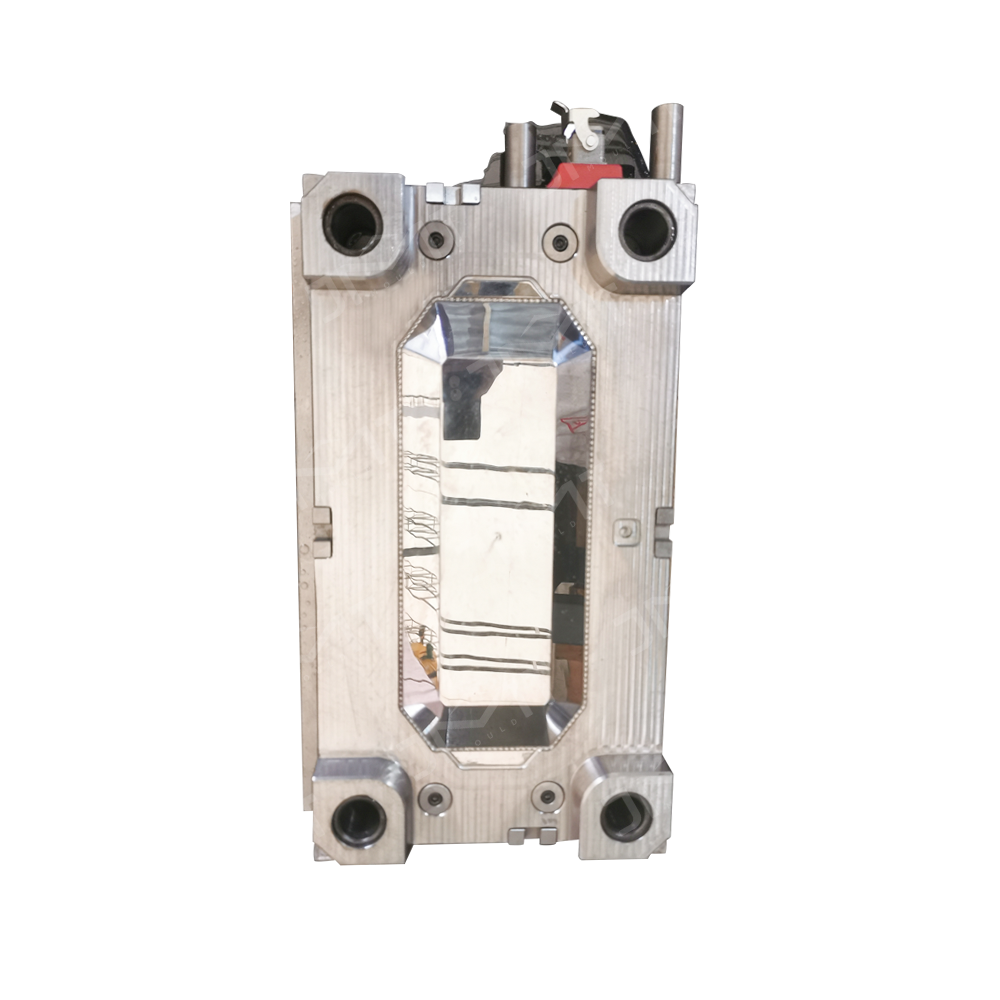

1 Tips hot runner pin gate

|

|

Manufacture time (day)

|

50 DAYS

|

|

Mould life

|

1,000,000

|

|

Cooling line connector type

|

DME NS350 SERIES quick coupling, excellent cooling system design, cooling design will as many as possible to cooling best

|

Precision Engineering:

The Rectangular Plastic Food Bowl Transparent Crystal Pattern Mould is a testament to precision engineering. Every aspect of this mould is meticulously designed to ensure the highest level of accuracy in crafting food bowls. It guarantees consistency and quality with every use.

Premium Materials:

Crafted from premium, high-quality materials, this mould is built to withstand the test of time. Its durability ensures that you can produce food bowls with the same level of excellence for years, saving you time and resources.

Versatile Design Options:

The mould offers endless design possibilities. Whether you desire classic rectangular bowls, unique crystal patterns, or customized designs, our mould empowers you to explore your creative vision. With 80 different design options available, your imagination is the only limit.

User-Friendly:

Creating stunning food bowls has never been more accessible. The Rectangular Plastic Food Bowl Transparent Crystal Pattern Mould is designed for user-friendliness, making it suitable for both professionals and enthusiasts. Our step-by-step instructions ensure that even beginners can achieve outstanding results.

Cost-Effective:

Investing in this mould is a cost-effective choice. Its long-lasting durability and versatility allow you to reduce production costs in the long run, making it a valuable addition to your workshop.

Eco-Conscious:

We are committed to sustainability. The Rectangular Plastic Food Bowl Transparent Crystal Pattern Mould is manufactured using eco-friendly processes and materials, minimizing its environmental impact. By choosing this mould, you're not only creating exquisite food bowls but also contributing to a greener planet.

Customization:

Recognizing that every project is unique, we offer customization options. Whether you want to adjust the mould size, crystal pattern, or texture, we can accommodate your specific requirements. With 80 customizable features, you can create food bowls that truly stand out.

Temperature Resistant:

This mould can withstand a wide range of temperatures, making it suitable for various materials, including PET, HDPE, PVC, and more. Its adaptability to different heating and cooling processes ensures consistent results.

Time-Saving:

Save time and effort with the Rectangular Plastic Food Bowl Transparent Crystal Pattern Mould. Its efficient design and user-friendly features streamline the production process, enabling you to create more bowls in less time.

Customer Support:

At your service 24/7, our team of experts is committed to providing exceptional customer support. We are here to address your inquiries, offer guidance, and ensure your satisfaction with our product.

In conclusion, the Rectangular Plastic Food Bowl Transparent Crystal Pattern Mould represents the pinnacle of excellence in food bowl production. With its precision engineering, premium materials, versatility, and user-friendliness, it provides an unparalleled solution for professionals and enthusiasts alike. Its cost-effectiveness, eco-conscious design, and customization options make it the go-to choice for all your food bowl-making needs. Explore the possibilities with 80 different design options, and craft excellence with the Rectangular Plastic Food Bowl Transparent Crystal Pattern Mould. Your journey towards creating exquisite food bowls starts here.

English

English Español

Español عربى

عربى