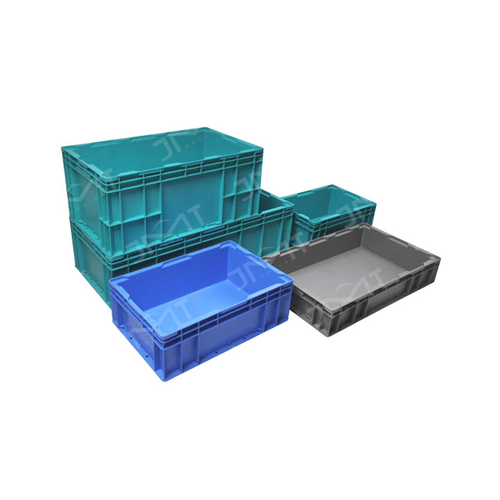

In recent years, the agriculture industry has witnessed a significant transformation in its practices and processes. One area that has undergone a remarkable change is the packaging and transportation of vegetables. Plastic crates, specifically designed for the purpose, have revolutionized the way farmers, distributors, and retailers handle and transport vegetables. At the heart of this revolution lies the vegetable crate plastic mould, a crucial component in the production of these efficient and durable crates. This article explores the significance of vegetable crate plastic moulds and their impact on the agriculture industry.

Enhancing Efficiency:

Vegetable crate plastic moulds play a vital role in optimizing the efficiency of packaging and transportation in the agriculture sector. These moulds are meticulously designed to create crates that maximize available space, allowing for easy stacking and storage. The standardized size and shape of the crates ensure compatibility with handling equipment, such as forklifts and conveyor systems, streamlining the entire logistics process. As a result, farmers and distributors can efficiently load, transport, and unload large quantities of vegetables, reducing handling time and minimizing potential damage.

Durability and Protection:

One of the key advantages of vegetable crate plastic moulds is their ability to produce crates that are highly durable and provide excellent protection to the enclosed vegetables. The moulds are made from robust materials, such as high-density polyethylene (HDPE) or polypropylene (PP), which are resistant to impact, moisture, and temperature variations. This durability ensures that the crates can withstand the rigors of transportation and storage without compromising the quality and freshness of the vegetables. Additionally, the moulds can be designed with features like interlocking mechanisms and reinforced corners, further enhancing the structural integrity of the crates.

Hygiene and Sanitation:

Maintaining hygiene and sanitation standards is of utmost importance when dealing with perishable goods like vegetables. Vegetable crate plastic moulds facilitate this by offering a hygienic packaging solution. The smooth, non-porous surfaces of the crates produced by these moulds prevent the accumulation of dirt, moisture, and contaminants. Moreover, the plastic material used in the moulds is easy to clean and sanitize, ensuring that the crates can be reused multiple times without compromising food safety. This not only reduces waste but also contributes to sustainable practices within the agriculture industry.

Customization and Adaptability:

Vegetable crate plastic moulds offer a high degree of customization and adaptability, catering to the diverse needs of farmers and distributors. The moulds can be designed to accommodate different sizes, shapes, and capacities, allowing for efficient packaging of various types of vegetables. Additionally, features such as stackable design, ventilation holes, and label holders can be incorporated into the moulds based on specific requirements. This flexibility ensures that the crates produced are tailored to meet the demands of specific vegetables and optimize their storage and transportation conditions.

Environmental Considerations:

While plastic is known for its negative impact on the environment, vegetable crate plastic moulds can still contribute to sustainability efforts. The durability and reusability of the crates significantly reduce the need for single-use packaging materials. Moreover, many moulds are now made using recyclable and eco-friendly plastics, further minimizing their environmental footprint. The agricultural sector can also explore options for using bio-based or biodegradable plastics in the production of vegetable crate plastic moulds, ensuring a greener approach to packaging and transportation.

Conclusion:

The vegetable crate plastic mould has emerged as a game-changer in the agriculture industry, providing a reliable and efficient solution for the packaging and transportation of vegetables. With their ability to enhance efficiency, ensure durability and protection, maintain hygiene standards, offer customization, and address environmental concerns, these moulds have become indispensable tools for farmers, distributors, and retailers. As the agriculture sector continues to evolve, the vegetable crate plastic

English

English Español

Español عربى

عربى