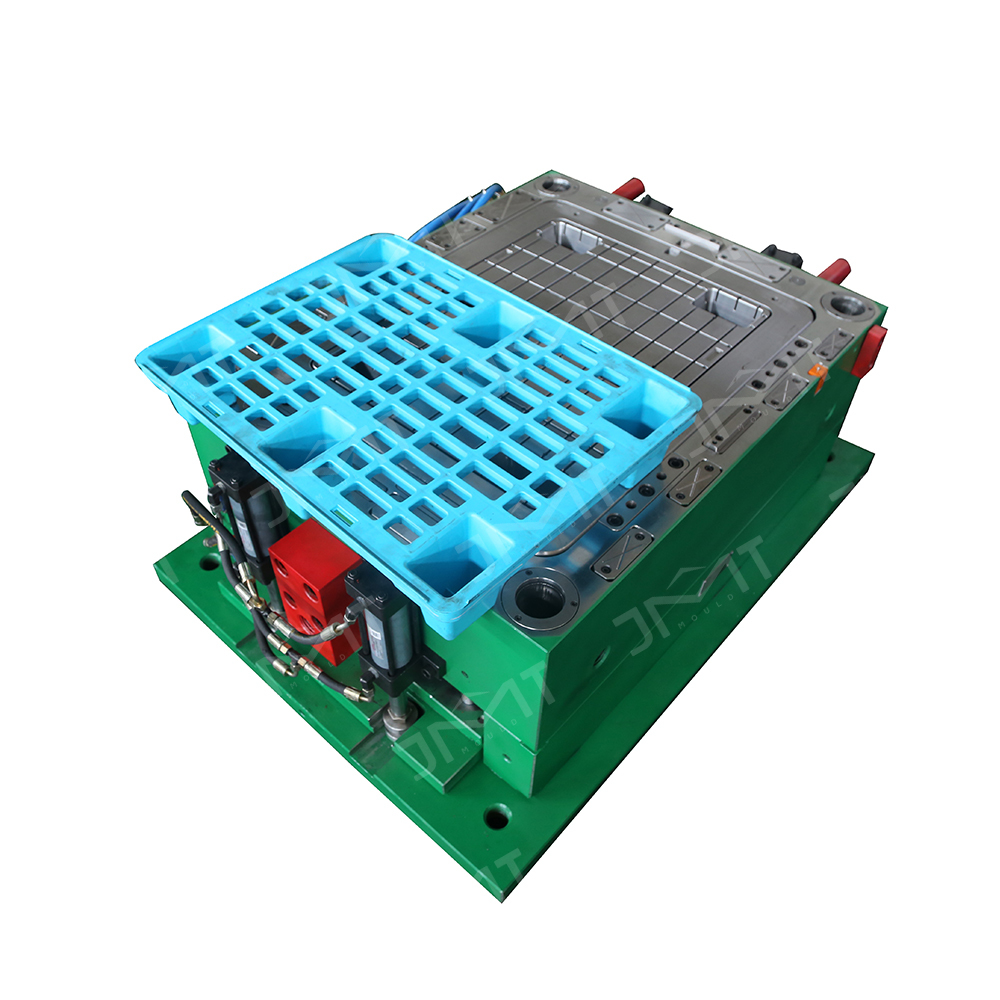

Wholesale Professional pallet mould Manufacturers

In the ever-evolving landscape of warehousing, the role of Professional pallet mould has become increasingly pivotal. As the dynamics of warehouses continue to change, driven by technological advancements and shifting operational paradigms, the adaptability of pallet molds has emerged as a critical factor in enhancing efficiency and productivity. This article delves into how the Professional pallet mould of the future are poised to seamlessly integrate with changing warehouse dynamics.

The Current Landscape

Before exploring the future, it's essential to understand the current state of warehouse dynamics. Warehouses are no longer mere storage spaces; they have become dynamic hubs where speed, precision, and adaptability are paramount. With the rise of e-commerce, just-in-time inventory systems, and the demand for quicker order fulfillment, warehouses are under immense pressure to optimize their operations.

Professional pallet mould, as integral components of material handling systems, play a vital role in this optimization process. They are not only responsible for maintaining the structural integrity of pallets but also contribute significantly to the overall efficiency of warehouse processes.

Adapting to Technological Advancements

One of the key aspects driving changes in warehouse dynamics is the rapid advancement of technology. Automation, robotics, and the Internet of Things (IoT) have already begun reshaping how warehouses operate. In this context, Professional pallet moulds of the future will need to seamlessly integrate with these technological advancements.

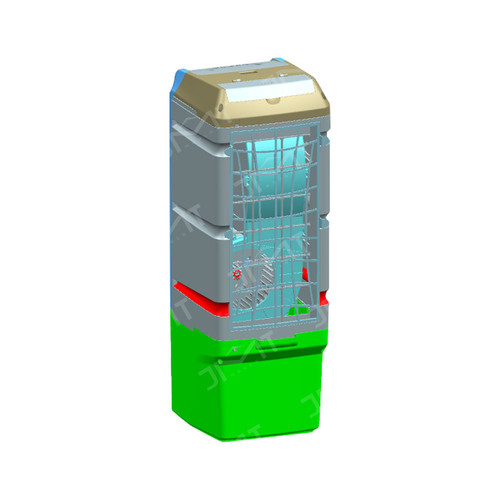

Smart Professional pallet moulds equipped with sensors and IoT connectivity will enable real-time monitoring of pallet conditions. These molds can relay information about factors such as load weight, temperature, and structural integrity, providing warehouse managers with valuable data to optimize storage and transportation processes. The ability to adapt to these technological changes will be crucial for pallet molds to remain relevant in the warehouses of the future.

Customization for Varied Product Types

The modern warehouse deals with a diverse range of products, from fragile electronics to heavy machinery. Professional pallet moulds must adapt to this diversity by offering customization options that cater to the specific needs of different product types.

Future Professional pallet moulds will be designed with modularity and adjustability in mind, allowing for quick and easy customization based on the characteristics of the products being stored or transported. This adaptability ensures that the molds can accommodate various shapes, sizes, and weights without compromising on safety or efficiency.

Enhanced Durability for Long-Term Reliability

As warehouses strive for increased operational efficiency, pallet molds must evolve to meet the demand for durability and long-term reliability. The molds of the future will be constructed using advanced materials and manufacturing techniques to ensure they can withstand the rigors of a high-paced warehouse environment.

The focus on durability goes beyond merely extending the lifespan of the molds. It directly contributes to minimizing downtime and maintenance costs, allowing warehouses to operate smoothly without interruptions. Professional pallet moulds that withstand the test of time will be an essential asset in the ever-changing landscape of warehouse dynamics.

Efficient Space Utilization

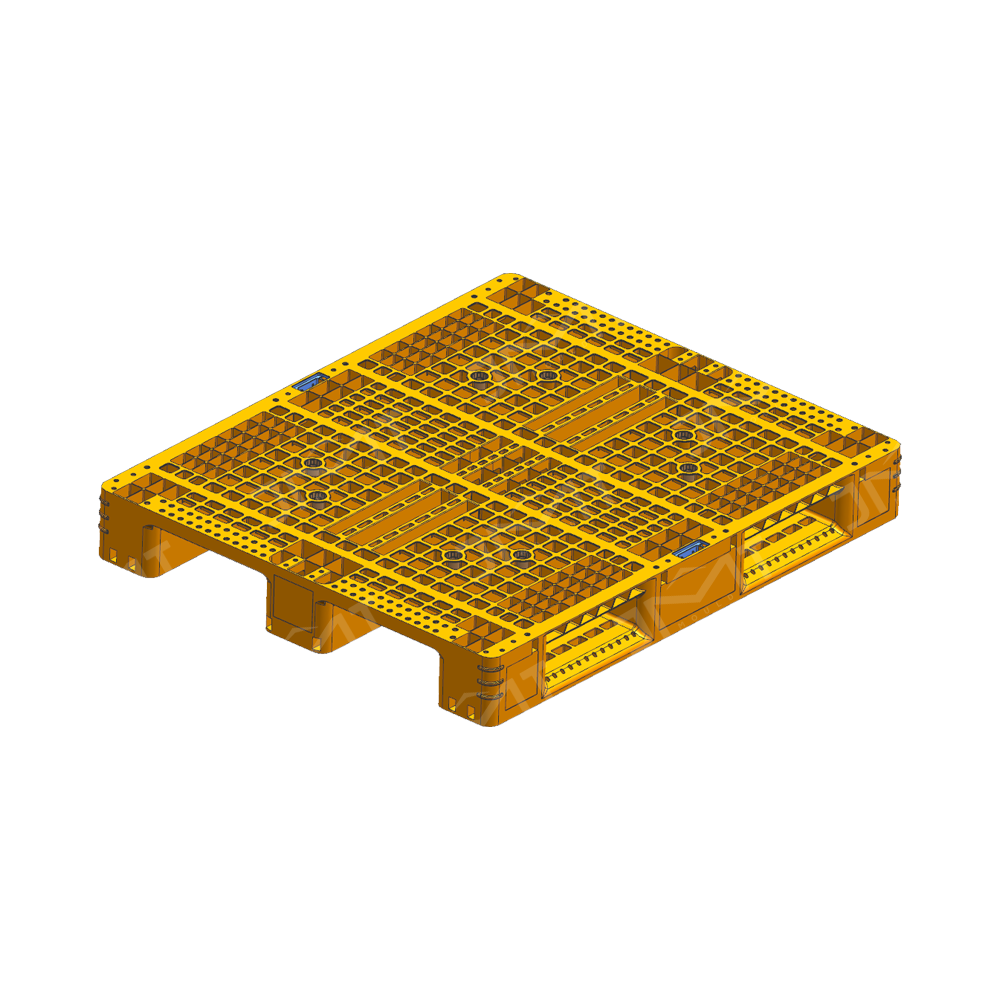

With the cost of warehouse space on the rise, optimizing storage capacity has become a priority for warehouse operators. Future pallet molds will be designed with a keen emphasis on efficient space utilization. This involves not only the arrangement of pallets within storage racks but also the design of the pallets themselves.

Collapsible and stackable Professional pallet moulds will enable warehouses to make the of their available space. This adaptability ensures that when pallets are not in use, they can be easily stored in a compact manner, freeing up valuable space for other operational needs. The ability to maximize space utilization will be a critical factor in the design of pallet molds in the future.

Integration with Sustainable Practices

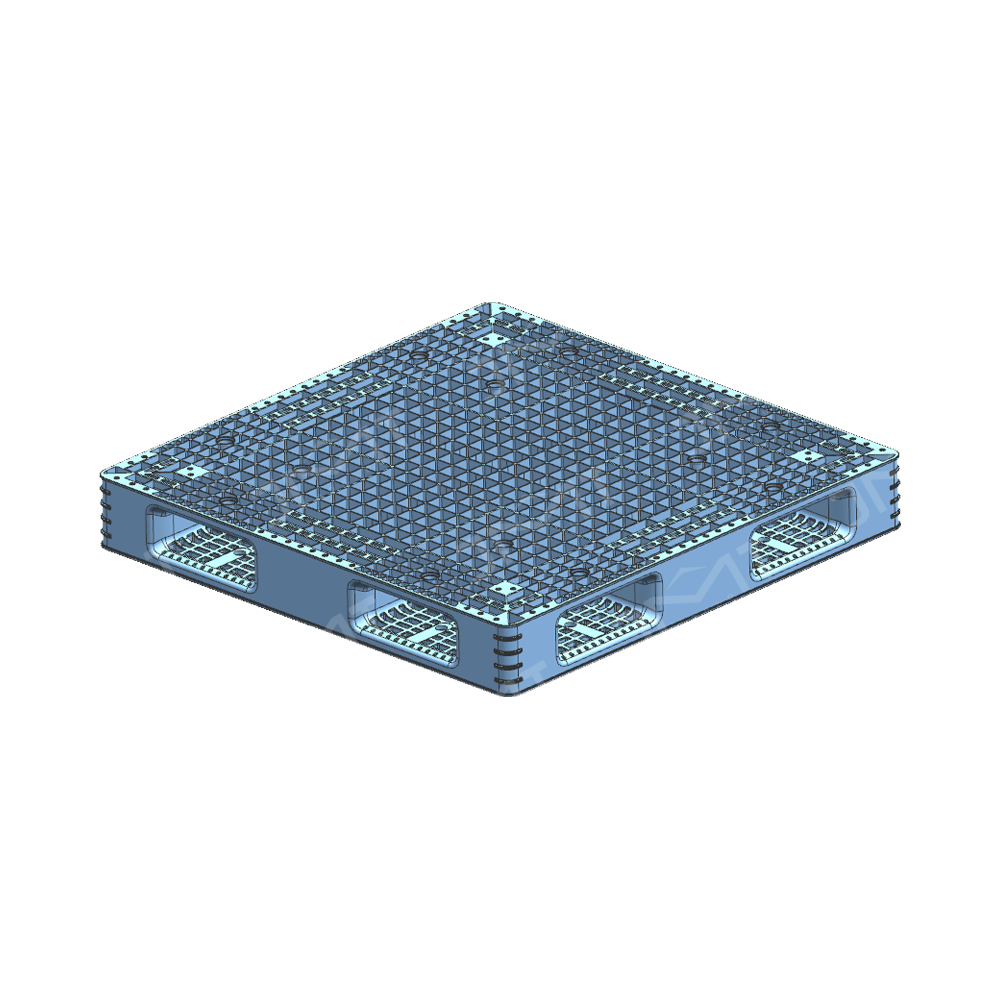

In the wake of increasing environmental consciousness, warehouses are actively seeking sustainable practices to reduce their ecological footprint. Professional pallet moulds of the future will align with these sustainability goals by incorporating eco-friendly materials and manufacturing processes.

Recyclable materials and energy-efficient production methods will be at the forefront of Professional pallet mould design. Additionally, the molds will be engineered to enhance the recyclability of the pallets they produce, contributing to a closed-loop system that minimizes waste and supports sustainable practices within the warehouse ecosystem.

Adapting to Shifting Supply Chain Dynamics

The modern supply chain is marked by volatility, with disruptions ranging from geopolitical events to global health crises. Professional pallet moulds must be adaptable to these uncertainties, ensuring that warehouses can respond swiftly to changes in the supply chain landscape.

Future Professional pallet moulds will prioritize flexibility in terms of production schedules and adaptability to varying demand levels. The ability to quickly switch between different pallet configurations and sizes will empower warehouses to navigate supply chain disruptions without compromising on efficiency. This adaptability will be a key factor in ensuring the resilience of warehouses in the face of unpredictable challenges.

In conclusion, the evolution of Professional pallet moulds is intricately linked to the changing dynamics of warehouses. The future of pallet molds lies in their ability to seamlessly integrate with technological advancements, accommodate diverse product types, enhance durability, optimize space utilization, align with sustainable practices, and adapt to shifting supply chain dynamics.

As warehouses continue to evolve into high-tech hubs of efficiency, the role of Professional pallet moulds cannot be understated. Their adaptability and innovative features will determine the success of warehouses in meeting the demands of the modern era. By embracing these changes and staying ahead of the curve, pallet molds will not only keep pace with warehouse dynamics but also contribute significantly to shaping the future of efficient and sustainable material handling.

English

English Español

Español عربى

عربى