In the ever-evolving landscape of furniture manufacturing, the use of plastic table molds has become a game-changer, offering a myriad of benefits that are reshaping the industry. The integration of these molds into the production process has not only streamlined the creation of dining furniture but has also introduced a new level of versatility, durability, and affordability. This article delves into the various ways plastic table molds are redefining the manufacturing of dining furniture.

Traditionally, dining furniture has been crafted from materials such as wood, metal, and glass. However, the advent of plastic table molds has introduced a new paradigm in furniture design and production. These molds are used to create plastic tables that are lightweight, easy to maintain, and cost-effective, making them an attractive option for both manufacturers and consumers.

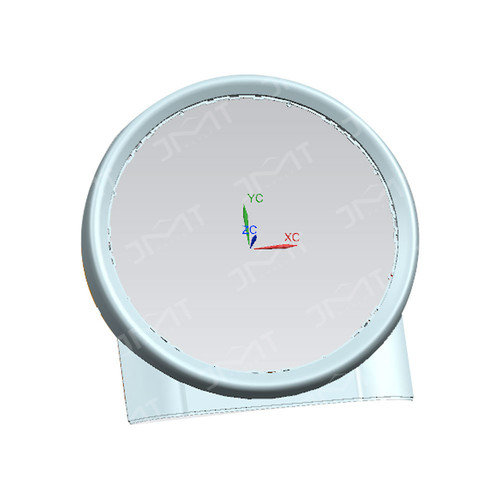

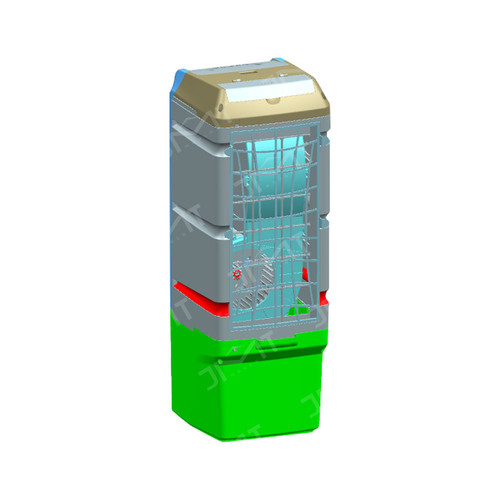

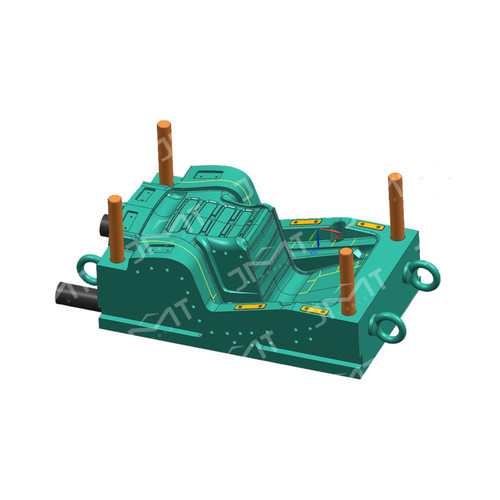

Plastic table molds are the backbone of modern plastic table production. They are designed to be used with various types of plastics, including but not limited to, polypropylene, ABS, and polyethylene. The molds are precision-engineered to produce tables with consistent dimensions and shapes, ensuring a high-quality end product every time.

One of the primary advantages of using plastic table molds is the efficiency it brings to the manufacturing process. The molds allow for the mass production of tables with minimal manual labor, reducing production time and labor costs. This efficiency is particularly beneficial for large-scale operations where the demand for dining furniture is high.

Plastic table molds offer a high degree of design flexibility. Manufacturers can create a wide range of table shapes, sizes, and styles using the same mold, simply by altering the plastic material or the mold's design parameters. This versatility allows manufacturers to cater to diverse market demands and preferences without the need for significant retooling.

Plastic tables produced using molds are known for their durability. They can withstand the rigors of daily use and are resistant to scratches, dents, and other forms of wear and tear. Additionally, these tables are easy to clean and maintain, requiring only a simple wipe with a damp cloth to remove dirt and stains.

The cost-effectiveness of plastic table molds is another significant factor contributing to their popularity. The initial investment in molds can be high, but the long-term savings in material and labor costs make it a worthwhile investment. Plastic tables are generally less expensive to produce than their wooden or metal counterparts, allowing manufacturers to offer competitive prices to consumers.

The use of plastic table molds also has environmental implications. While plastic is often criticized for its environmental impact, the use of recycled plastics in molds is becoming more prevalent. This not only reduces the demand for new plastic production but also helps in managing plastic waste. Moreover, the longevity of plastic tables means they have a longer service life, reducing the frequency of replacement and waste generation.

With plastic table molds, manufacturers can easily offer customized and personalized products. Whether it's a specific color, pattern, or design, the flexibility of plastic molding allows for unique pieces that can cater to individual tastes and preferences.

Consumer preferences are shifting towards modern, minimalist designs that are both functional and aesthetically pleasing. Plastic table molds enable manufacturers to create sleek, contemporary designs that align with these preferences. Furthermore, the lightweight nature of plastic tables makes them ideal for small spaces and easy relocation, appealing to urban consumers with limited space.

Despite the numerous advantages, the use of plastic table molds also presents challenges. One such challenge is the perception of plastic as an inferior material compared to wood or metal. However, manufacturers are addressing this by focusing on the quality and durability of their products, as well as educating consumers about the benefits of plastic furniture.

The future of dining furniture manufacturing looks promising with the continued use of plastic table molds. As technology advances, we can expect further improvements in mold design and plastic materials, consequently even higher quality and more innovative dining furniture.

In conclusion, plastic table molds are redefining dining furniture manufacturing by offering a combination of efficiency, versatility, durability, and cost-effectiveness. As the industry continues to embrace these molds, we can expect to see a wider range of high-quality, affordable, and stylish dining furniture options available to consumers. The integration of plastic table molds into the manufacturing process is a testament to the innovation and adaptability of the furniture industry, ensuring its continued growth and relevance in the market.

English

English Español

Español عربى

عربى