Supply Professional Industrial Mould Wholesalers Exporter

An Professional Industrial Mould is a crucial piece of equipment in countless manufacturing processes, due to its primary role in shaping raw materials into a wide array of consumer goods. Industrial moulds have distinct characteristics, an understanding of which is essential in modern industrial manufacturing. In the creation of objects of all shapes and sizes, industrial moulds reign supreme.

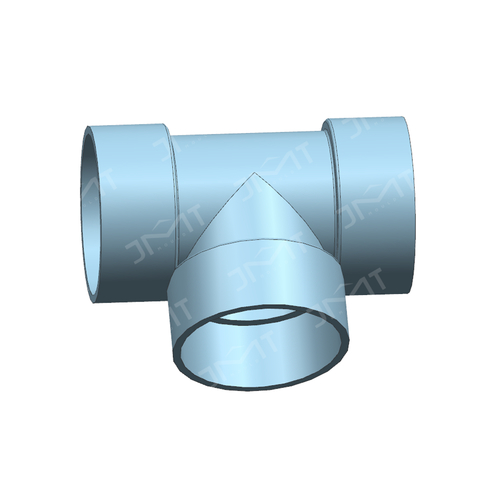

Essentially, Professional Industrial Mould are specifically designed tools employed in the manufacturing sector to produce components in large volumes. These voluminous outputs are achieved through the moulding of raw materials such as metal, plastic, or glass, in the industrial mould. Constructed to serve multiple processes, Professional Industrial Mould cater to a plethora of manufacturing technologies including injection moulding, die casting and glass blowing among others.

The nature of the raw materials that an Professional Industrial Mould handles necessitates it to be constructed from highly durable substances. Typically, the composition of an industrial mould includes metals which are known for their robustness and longevity. Often, you'll find materials like steel, aluminium, beryllium copper, and other alloys being used for crafting industrial moulds.

The utilisation of strong metals in manufacturing Professional Industrial Mould ensures that the mould can withstand high-pressure levels during the production process. An Professional Industrial Mould formed from such resilient materials experiences lower wear, extending the duration for which it remains functional. A long-lasting industrial mould, therefore, guarantees the sustainability of manufacturing operations.

To appreciate the full spectrum of Professional Industrial Mould, it's necessary to delve into the varied types available in the market. The function that an Professional Industrial Mould is to fulfil often predominantly dictates its design. For instance, a blow moulding industrial mould is vastly different from, say, a compression moulding industrial mould. Yet, despite their disparate designs, all industrial moulds have a common role – that is to deliver uniform and high-quality outputs.

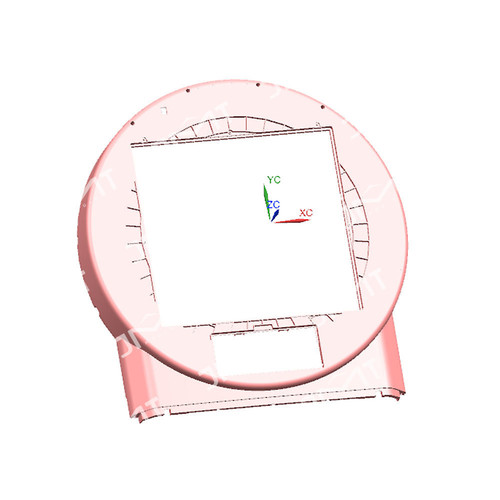

A key aspect to highlight regarding the Professional Industrial Mould is its production process. Being a highly critical component in manufacturing, great precision goes into crafting an industrial mould. The creation of these tools often involves steps such as design, mould base selection, mould material selection, manufacture, test, and inspection. Each stage is meticulously executed to maintain the mould's integrity and ensure its durability.

The possibilities in manufacturing that an Professional Industrial Mould opens up make it a hugely valuable asset. Industrial moulds are commonly found in industries like electronics, where they aid in the production of components. Also, in the automotive industry, Professional Industrial Mould contribute to the manufacture of parts such as panels and bumpers, thus playing an integral role in the construction of vehicles.

Moreover, sustainability is a growing trend in the industrial landscape, and the industrial mould is central to this progress. By employing a robust Professional Industrial Mould, manufacturers can cut down on wastage by ensuring only the necessary amount of raw material is used. Also, being durable, an industrial mould reduces the need for frequent replacements. Therefore, the industrial mould has considerable green credentials, making it an asset that aligns with environmental objectives.

Despite its immense benefits, the Professional Industrial Mould is not without its challenges. For instance, the high cost of these moulds is often seen as a significant barrier, particularly for smaller enterprises. Also, maintaining an industrial mould can be demanding, with both scheduled and unscheduled maintenance required to keep the mould in optimal condition.

Nevertheless, the advantages of the Professional Industrial Mould far outweigh its associated costs and maintenance challenges. In fact, industrial mould has proven to be one of the critical drivers of efficiency in modern industrial operations. As it facilitates the mass production of intricate parts quickly, an Professional Industrial Mould is indeed an invaluable industrial asset.

Invariably, Professional Industrial Mould have transformed and streamlined the manufacturing industry, thanks to their unrivalled efficiency and versatility. As industries aim for greater cost-effectiveness, quality and speed in production, the industrial mould emerges as the go-to tool that encapsulates these manufacturing objectives. Therefore, understanding and harnessing the power of the industrial mould is non-negotiable for any forward-thinking enterprise.

In conclusion, the Professional Industrial Mould represents a cornerstone of contemporary manufacturing. Its role in shaping raw materials into finished products – in a quick, precise, durable and efficient manner – earns it crucial importance in today's production lines. As innovations continue to impact the industry, the Professional Industrial Mould is poised to evolve in tandem, thereby shaping the future of manufacturing.

English

English Español

Español عربى

عربى