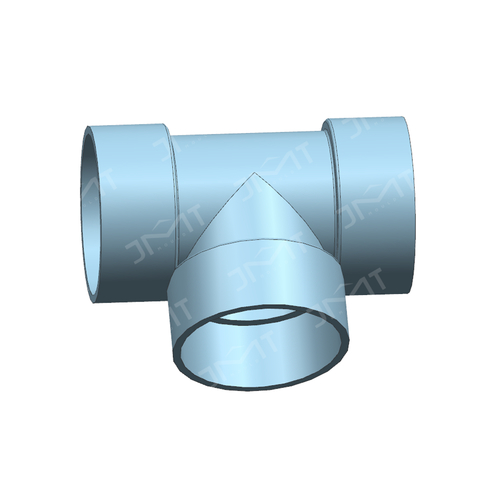

Direct Selling Design Pipe Fitting Mould Manufacturers

Design Pipe Fitting Moulds have become an essential component in the plumbing industry, transforming the way plumbing systems are designed and installed. These moulds facilitate efficient and cost-effective production of pipe fittings, ensuring proper connections and reducing the risk of leaks. With the help of these moulds, plumbing professionals can create precise and durable fittings, enhancing the overall performance of plumbing systems. In this article, we will delve into the advancements in pipe fitting mould technology and their impact on the plumbing industry.

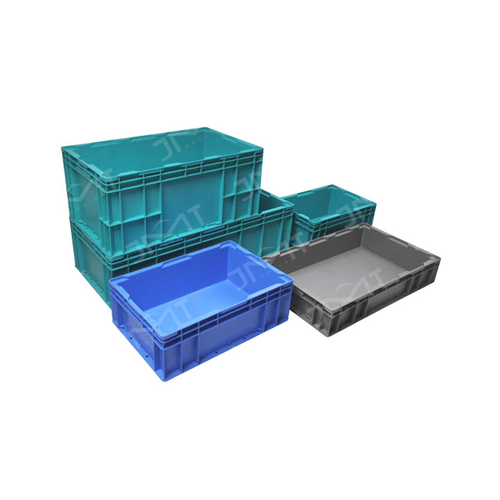

1. Increased Efficiency and Cost-Effectiveness:

The use of Design Pipe Fitting Moulds has revolutionized the manufacturing process, making it significantly more efficient. These moulds enable mass production of pipe fittings with minimal manual labour, reducing production time and costs. The precise designs produced by the moulds guarantee accurate dimensions and consistent quality, eliminating the need for additional adjustments or modifications. This streamlining of the manufacturing process has not only increased productivity but also reduced production costs, making pipe fittings more affordable for consumers.

2. Enhanced Durability and Strength:

One of the key advantages of Design Pipe Fitting Moulds is their ability to create strong and durable fittings. The moulds are made from high-quality materials, ensuring that the produced fittings can withstand high pressure and rough handling. This enhances the longevity of the plumbing systems, mitigating the risk of frequent repairs or replacements. Additionally, the uniformity of the fittings produced by the moulds ensures a tight and secure connection, reducing the likelihood of leaks or water damage.

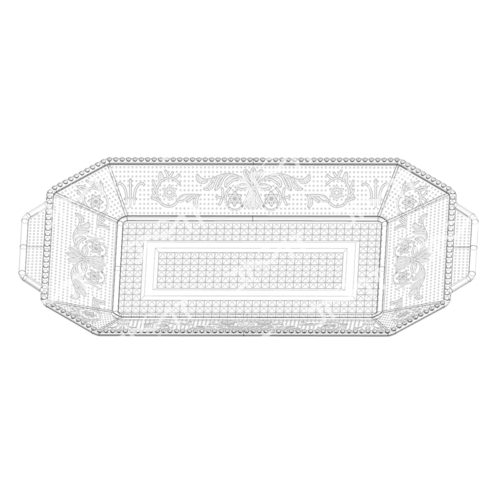

3. Customization and Versatility:

Design Pipe Fitting Moulds offer a wide range of customization options, allowing plumbing professionals to create fittings tailored to specific requirements. Whether it's a unique shape, size, or design, these moulds can easily accommodate diverse needs. This versatility has greatly expanded the possibilities in plumbing system design, enabling creative and innovative solutions. Moreover, the use of moulds ensures consistency in the production of customized fittings, maintaining a high level of quality and performance.

4. Integration of Advanced Technologies:

The incorporation of advanced technologies in Design Pipe Fitting Moulds has further revolutionized the plumbing industry. Computer-aided design (CAD) software allows for precise and detailed designs, eliminating any margin of error. This software enables virtual simulations, allowing manufacturers to identify potential flaws or weaknesses in the design before production begins. Additionally, 3D printing technology has made prototyping easier and faster, reducing lead times and promoting quicker innovation. The integration of such technologies in Design Pipe Fitting Moulds has enhanced the overall efficiency and accuracy of the production process.

5. Sustainable Solutions:

Design Pipe Fitting Moulds play a significant role in promoting sustainability in the plumbing industry. By facilitating precise manufacturing, they reduce material waste, minimizing the industry's environmental footprint. Furthermore, with the use of durable materials and precise designs, the need for constant repairs and replacements is significantly reduced. This leads to a decrease in the consumption of resources and supports a more sustainable approach to plumbing systems.

Conclusion:

Design Pipe Fitting Moulds have brought about a paradigm shift in the plumbing industry, offering efficiency, durability, customization, and sustainability. These innovative moulds have transformed the manufacturing process, making it more cost-effective and enabling the creation of precise and durable fittings. With their ability to integrate advanced technologies, pipe fitting moulds have set new standards for the industry, leading to higher quality plumbing systems. As the industry continues to evolve, it is evident that pipe fitting moulds will remain a critical component in the future of plumbing.

English

English Español

Español عربى

عربى