Supply Custom crate mould Company

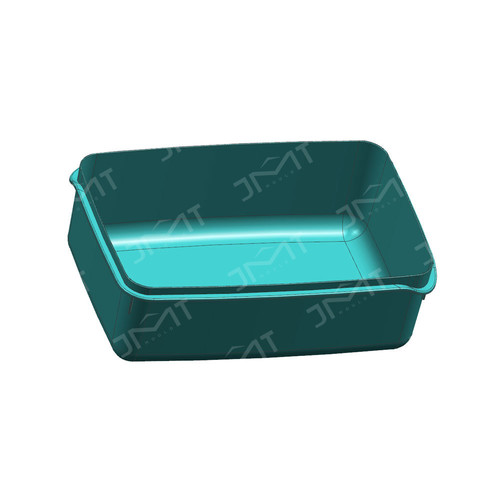

Custom crate moulds play a crucial role in the manufacturing industry, as they are responsible for creating durable and efficient crates for a wide range of applications. These crates are used to transport and store various goods, ensuring their safe delivery to end-users. In this article, we will delve into the secrets behind innovative crate mould designs, exploring the factors that contribute to their durability and effectiveness.

Understanding the Importance of Durability:

Durability is key when it comes to Custom crate mould designs. Crates need to withstand tough handling, stacking, and storage conditions, ensuring that the goods inside remain intact. By using high-quality materials and employing advanced techniques, manufacturers can create moulds that produce durable and long-lasting crates.

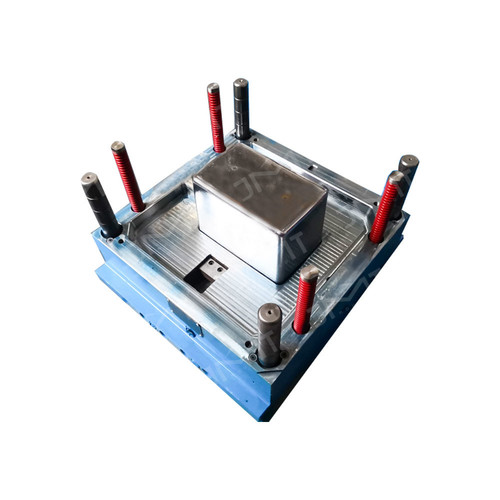

Material Selection:

The choice of materials for Custom crate moulds significantly impacts their durability. While there are various options available, such as steel, aluminium, and even certain plastics, high-quality steel is a popular choice due to its strength and longevity. Steel crate moulds can withstand the stress and wear associated with the manufacturing process, resulting in reliable and sturdy crates.

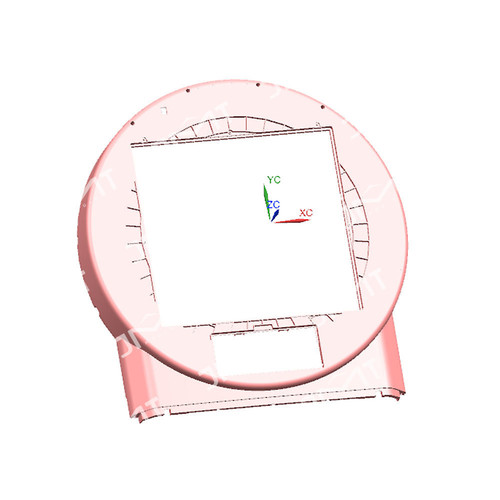

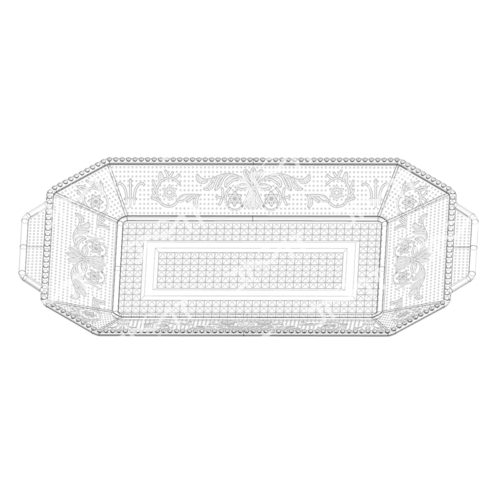

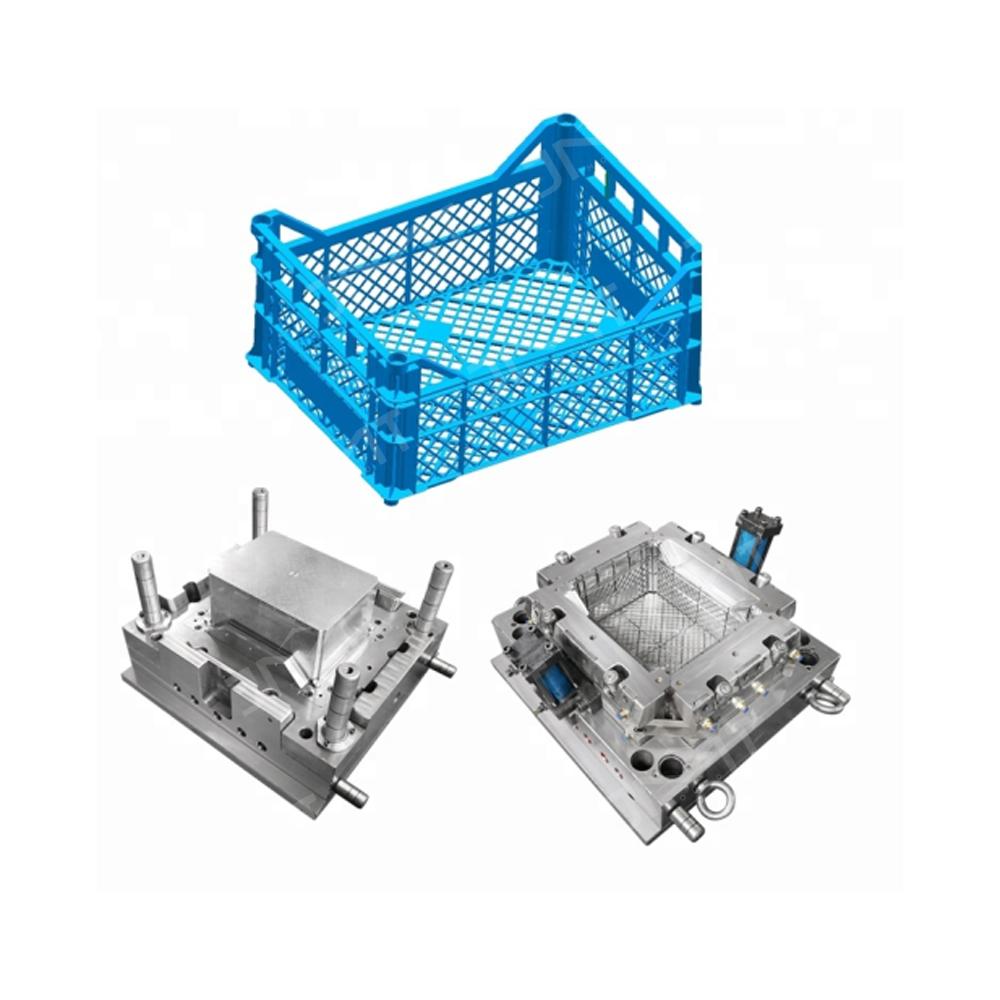

The Role of Design:

Design plays a crucial role in achieving durability in Custom crate moulds. By employing innovative design techniques, manufacturers can create moulds that are optimized for strength and longevity. This includes strategic placement of reinforcement ribs, ensuring proper ventilation channels, and incorporating additional features that enhance the overall durability of the crate.

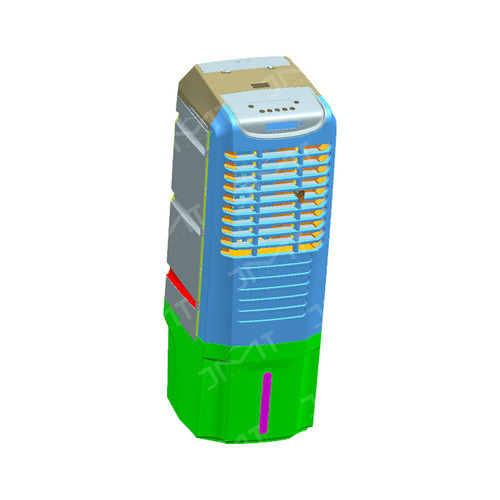

Precision and Accuracy:

Achieving durability in Custom crate moulds requires precision and accuracy throughout the manufacturing process. Advanced machining techniques and technologies are utilized to ensure that every component is precisely crafted to fit together seamlessly. This attention to detail minimizes the risk of defects and ensures consistency in the final product.

Heat Treatment:

Heat treatment is another key factor in ensuring the durability of Custom crate moulds. By subjecting the moulds to controlled heating and cooling processes, manufacturers can enhance their hardness and resistance to wear. This extends the lifespan of the moulds and ensures that they can withstand repeated use and maintain their integrity over time.

The Importance of Proper Maintenance:

Even with innovative designs and high-quality materials, Custom crate moulds require proper maintenance to ensure their longevity. Regular cleaning, inspection, and necessary repairs should be carried out to prevent any deterioration of the moulds. This proactive approach helps in identifying potential issues early on and taking corrective measures to avoid significant damages.

Advanced Technologies and Automation:

With advancements in technology, the manufacturing process for crate moulds has become more efficient and precise. Computer numerical control (CNC) machines and automated systems have revolutionized the industry, allowing for faster production and higher accuracy in creating complex mould designs. technologies contribute to the durability and consistency of Custom crate moulds.

Continuous Improvement and Innovation:

To meet the demands of an ever-evolving market, crate mould designs are constantly improved and innovated upon. Manufacturers invest in research to enhance the durability, efficiency, and functionality of their moulds. This includes the incorporation of new materials, advanced processes, and the exploration of innovative design concepts.

Conclusion:

The durability of Custom crate moulds is essential for the successful transportation and storage of goods. Through the careful selection of materials, innovative design techniques, precise manufacturing processes, and continuous improvement, manufacturers can create high-quality moulds that produce durable and reliable crates. The secrets behind innovative crate mould designs lie the meticulous attention to detail and the pursuit of excellence in every aspect of the manufacturing process. By embracing these secrets, manufacturers can ensure the satisfaction of their customers and meet the ever-increasing demands of the industry.

English

English Español

Español عربى

عربى